They have been warned that this would effectively make electronics unavailable in Sweden (even if it were removed from PCBs it is used extensively in "plastic" packaged electronic components like integrated circuits and tantalum capacitors). In the electronics industry, many customers in smt chip processing will inquire whether to provide halogen-free technology. See the article " City sued over ban on children's products using suspect chemicals Plaintiffs say state law pre-empts the local ordinance."Īlso, Sweden is investigating whether to restrict TBBPA (tetrabromobisphenol A), which is used in PCBs.

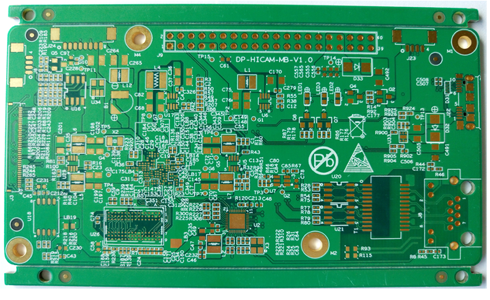

However, the American Chemistry Council, which is the chemical industry lobbying organization, filed suit recently and succeeded in obtaining a temporary injunction. This would restrict the sale of electronics intended for this age group due to TBBPA in PCBs and components. See my article, Bisphenol-A and phthalates banned from electronic toys. San Francisco banned bisphenol A in products and child care items for infants/toddlers under 3 years of age. This circuit The Impact of Halogen Free PCB in. Halogen PCB has become so popular in the electronic industry. Hence, the use of safe materials for fabricating circuit boards is advised. Some materials cause hazards to the environment. The fabrication of PCB requires the use of environmentally-friendly material. Lead is another toxic element avoided by most industries. The PCB industry is a vast one that entails different forms of circuit boards. It has a good dielectric constant Enhances manufacturing and process of multilayer PCBs. This means that this board can function well at higher temperatures. There is pressure from NGOs like Greenpeace to remove all bromines from electronics, however, and iNEMI has a project underway to identify replacements in PCBs. Halogen free PCB features a higher glass melting point (TG). Outside of San Francisco, there is no current legislation or regulation (and there is no such thing as 'global legislation' -that would require a global government) in the world that requires removal of all halogens from PCBs. Have there been any generic reliability risks identified for Halogen Free PCBs which are to be used in Aerospace or Military applications? The dielectric constant, dissipation factor and moisture diffusivity of based material Halogen. What global legislation dictates the specification of Halogen Free PCBs? Is the Montreal Protocol included? The based material of halogen free PCBs are free of Halogen.

0 kommentar(er)

0 kommentar(er)